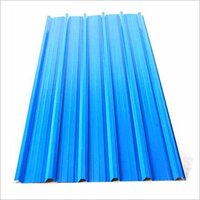

Color Coated Sheet refers to a type of steel sheet that has been coated with a layer of paint or other protective material to protect against corrosion, weathering, and other environmental factors. The coating is typically applied using a process known as coil coating, which involves passing the steel sheet through a series of rollers while the coating is applied. The color-coated sheet is available in a range of colors and finishes, including glossy, matte, and textured finishes.

Versatile ApplicationOur color coated sheets are suitable for diverse uses, including roofing, cladding, wall panels, and both industrial and residential projects. Their robust weatherproofing and UV resistance make them ideal for demanding environments, such as warehouses and factories, as well as for the aesthetics of modern homes.

Advanced Coating TechnologyChoose from PE, SMP, PVDF, or HDP coatings to meet specific requirements. These coatings provide excellent resistance to humidity, acid rain, and general weathering, ensuring structures remain protected and visually appealing over time. The sheets comply with recognized standards like IS 14246, JIS G3312, and ASTM A755.

Customization & Quality AssuranceSelect from an extensive range of RAL colors, sheet thicknesses (0.12mm - 1.2mm), and customizable lengths. Supplied with either plain or crimped edges, and packed to export standards, each batch undergoes strict quality checks for strength, durability, and finish, guaranteeing long-lasting performance.

FAQs of Color Coated Sheet:

Q: How are color coated sheets manufactured and finished?

A: Color coated sheets start as galvanized or galvalume steel, processed with cold rolling and then coated using advanced PE, SMP, PVDF, or HDP technologies to achieve high durability. The sheets are pre-painted and treated for excellent corrosion, UV, and weather resistance.

Q: What range of applications can these color coated sheets be used for?

A: These sheets are perfect for roofing, cladding, wall paneling, and a variety of construction projects, including warehouses, industrial sheds, and residential buildings, thanks to their excellent durability and weatherproof features.

Q: When should I choose specific coating types such as PE, SMP, PVDF, or HDP?

A: Select PE for general purposes, SMP for enhanced scratch resistance, PVDF for superior color retention and UV resistance, or HDP for outstanding weatherability in harsh environments. The best choice depends on your projects specific exposure and longevity needs.

Q: Where can these color coated sheets be installed?

A: They are engineered for both indoor and outdoor applications, performing reliably in industrial, commercial, and residential locations throughout India and beyond, wherever strong environmental and fire resistance is essential.

Q: What is the process for customizing the size and shape of the sheets?

A: You can specify desired lengths and widths (from 600mm to 1250mm wide) according to your project requirements. Thickness can be selected between 0.12mm to 1.2mm, and the sheets can be supplied as plain or crimped-edged, ensuring a tailored fit for every installation.

Q: What benefits do color coated sheets offer over traditional building materials?

A: They provide high strength-to-weight ratio, excellent fire and environmental resistance, vivid color options, and long lifespan with minimal maintenance, making them a cost-effective and aesthetically versatile solution for modern construction.

Our Products

Our Products